Waterjet cutting is a process in which a supersonic stream of water, usually combined with a granular abrasive, is used to cut parts. Suitable for cutting everything from foam to steel, waterjet cutting is a versatile technology that can cut with exceptional accuracy and edge quality. These attributes make it a preferred cutting method for producing precise, high-quality parts used in aircraft, automobiles, architectural systems, and more.

How Does a Waterjet Work?

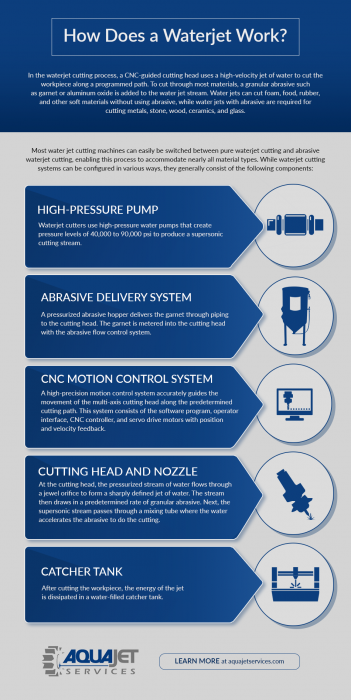

In the waterjet cutting process, a CNC-guided cutting head uses a high-velocity jet of water to cut the workpiece along a programmed path. To cut through most materials, a granular abrasive such as garnet or aluminum oxide is added to the water jet stream. Water jets can cut foam, food, rubber, and other soft materials without using abrasive, while water jets with abrasive are required for cutting metals, stone, wood, ceramics, and glass.

Most water jet cutting machines can easily be switched between pure waterjet cutting and abrasive waterjet cutting, enabling this process to accommodate nearly all material types. While waterjet cutting systems can be configured in various ways, they generally consist of the following components:

Most water jet cutting machines can easily be switched between pure waterjet cutting and abrasive waterjet cutting, enabling this process to accommodate nearly all material types. While waterjet cutting systems can be configured in various ways, they generally consist of the following components:

- High-pressure pump. Waterjet cutters use high-pressure water pumps that create pressure levels of 40,000 to 90,000 psi to produce a supersonic cutting stream.

- Cutting head and nozzle. At the cutting head, the pressurized stream of water flows through a jewel orifice with a diameter as small as a hair to form a sharply defined jet of water. For abrasive waterjet cutting, the stream then draws in a predetermined rate of granular abrasive. Next, the supersonic stream passes through a mixing tube or waterjet nozzle, where the water accelerates the abrasive. This combined stream has enough kinetic energy to cut through hard materials over a foot thick.

- Catcher tank. After cutting the workpiece, the energy of the jet is dissipated in a water-filled catcher tank.

- Abrasive delivery system. A pressurized abrasive hopper delivers the garnet through piping to the cutting head. The garnet is metered into the cutting head with the abrasive flow control system.

- CNC motion control system. A high-precision motion control system accurately guides the movement of the multi-axis cutting head along the predetermined cutting path. This system consists of the software program, operator interface, CNC controller, and servo drive motors with position and velocity feedback.

What Can a Waterjet Cut?

A waterjet cutter can be adapted for a huge variety of materials. This versatility allows it to cut through an impressive range of materials, including:

- Waterjet cutting is a cold-cutting technique, allowing it to cut metals without warping them or thermally altering their properties. Carbon steel, aluminum, titanium, and other metals are often cut with waterjets to create high-quality, high-precision components used in critical applications.

- While superalloys are difficult to cut using traditional methods, waterjet cutting allows them to be cut quickly and accurately without work hardening. Superalloy parts created with waterjet cutting are used in everything from jet and rocket engines to submarines and nuclear reactors.

- Plastics. Waterjets can cut plastics with a wide range of densities and thicknesses, making it an efficient method for producing high-quality plastic parts used in medical devices, electrical insulating products, food manufacturing equipment, and more.

- Glass. With the ability to pierce through glass without shattering it, waterjet cutting is ideal for producing mirrors, window panels, tabletop inlays, solar panels, and other custom-shaped glass products.

- Stone and tile. Stone, tile, marble, granite, and other materials can be efficiently and precisely cut into various shapes with waterjet cutting. Waterjets are commonly used to cut decorative inlays, medallions, and logos.

- The waterjet cutting process excels with difficult-to-cut ceramic materials, making it a preferred cutting option for creating electrical insulating ceramic parts used in aerospace and electronics applications.

- Waterjet cutting can produce the intricate shapes and profiles required for the formation of custom foam cases, dividers, insert materials, padding, and other products. Waterjets cut foam without using an abrasive.

- Pure waterjet cutting can create rubber gaskets, seals, and insulation components with clean edges, precise corners, notches, vent holes, and other specialized features.

Benefits of Waterjet Cutting

A few of the benefits that set waterjet cutting apart from other cutting techniques include:

- Cost-effectiveness. Compared with other high-precision cutting methods, the cost of operating a waterjet cutter is competitive. Other cost- and time-saving benefits are realized through fast drawing-to-cutting transition times, quick setup, and rapid cutting speeds—enabling shorter turnaround times on jobs.

- Superior edge quality.The smooth cuts created with waterjets have a minimal burr, saving time and money by reducing or eliminating the need for secondary finishing.

- Exceptional accuracy.Waterjet cutting is capable of achieving tolerances as close as +/- 0.002″ (+/- 0.05 mm), depending on the system. This capability makes it a preferred choice for high-precision parts requiring intricate designs and tight tolerances. When more accuracy is required, waterjets are a natural fit for finish machining processes because a waterjet-cut part has pristine, unhardened cut faces.

- No heat-affected zones. As a cold cutting process, waterjet cutting eliminates warping, hardened edges, and inaccuracy due to thermal expansion during cutting. This is especially important when working with heat-sensitive materials or creating parts that require extremely tight tolerances.

- Green benefits. Waterjet cutting is an inherently eco-friendly process that eliminates slag formation, toxic fumes, and smoke that are common to thermal cutting methods such as plasma or laser. Waterjet cutting also does not use chemicals or lubricants to cut. Furthermore, most of the waste material is finely crushed garnet—an environmentally benign by-product.

Expert Waterjet Services from AquaJet Services

With its versatility and precise cutting capabilities, waterjet cutting has become a popular cutting technique in a growing number of industries. At AquaJet Services, state-of-the-art waterjet cutting equipment and more than 30 years of fabrication experience allow us to provide solutions for even the most complex cutting challenges. We use 5-axis waterjets to cut complex angles and features with exceptional precision, and we have experience with cutting most materials and thicknesses. We also are a full-service fabricating shop offering design services, so we can take your project at any stage in the design process and see it through to completion.

To learn more about our waterjet cutting capabilities and how we can assist you with your next project, please contact us today.