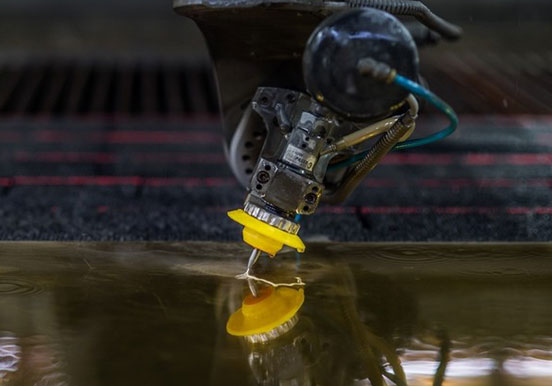

Waterjet Cutting

The waterjet is probably the most versatile cutting tool in the world, so most likely we can cut your material. We have successfully cut every material we have attempted except for tempered glass, and we have cut material thicknesses from shim stock that is thinner than paper up to stainless steel that is thicker than 18 inches.

The waterjet is probably the most versatile cutting tool in the world, so most likely we can cut your material. We have successfully cut every material we have attempted except for tempered glass, and we have cut material thicknesses from shim stock that is thinner than paper up to stainless steel that is thicker than 18 inches.

At AquaJet Services, we maximize our cutting performance by using 5-axis waterjets that offer the highest cutting precision and pressures available today. Our waterjets use 100-horsepower intensifiers to pressurize water to 87,000 psi. At the cutting head, the water is accelerated to a speed of nearly 2,500 miles per hour!

“We have cut shim stock that is thinner than paper and stainless steel that is thicker than 18 inches!”

We have waterjets with cutting envelopes as large as 118″ x 275″ x 12″; however, the cutting tables can be modified to accommodate even greater thicknesses.

Can We Do Your Job?

If your cutting job has some unusual requirements, we would be happy to discuss it with you. We rarely turn jobs away, but rather welcome opportunities to try new things and to continue learning. The result of this is that we have accumulated deep knowledge about waterjet cutting—its strengths and limitations, as well as the cutting characteristics of a wide variety of materials.

We have cut almost every material—metals (all types), brittle materials (stone, glass, ceramic), and softer materials (rubber, foam, plastics). We’ll be glad to do your cutting for you!

5-axis Waterjet Cutting

Our Flow® waterjets have Dynamic XD® cutting heads which can cut angles up to 60 degrees from vertical. In addition to straight and curved bevels, we can cut countersinks and complex surfaces where the cut angle is constantly changing. The tool path is generated directly from a 3D CAD file. With the ability to create machine code via a 3D solid model, it is possible to go from a concept to a physical part very quickly.

Taper Compensation

Waterjet cutting inherently produces a tapered cut. However, the Dynamic XD® cutting heads compensate for this taper in order to produce true parts without taper at any cut speed. With this feature, you can get a precise part as measured on both the top and bottom faces without having to pay for ultra-fine cut quality.

Precision

Let’s talk about your accuracy requirements. As a rule, we can hold tolerances of +/- 0.005″ or better in thicknesses up to 1″ in hard materials. However, it is important to understand that better tolerances require slower feed rates and more setup time, which directly translates to higher costs. While +/- 0.005” is attainable, loosening the tolerance to +/- 0.010″ already reduces the price significantly. If there are no specifications to be met, the parts should be within +/- 0.015″. Read our article “Waterjet Accuracy” for a better understanding of the capabilities and limitations of waterjets.